Operating Conditions

RF Transformers should always operate within safe limits of temperature and

linearity. Most amateur applications of matching transformers relate to baluns

in antenna systems, but they are also used as interstage or output transformers

in transmitters. Where possible windings should be made from suitable coax

cable. In some cases it is necessary to use twin line made from enamelled

copper wire (ecw) which has been spaced to achieve the desired line impedance.

EXCEL Programs which design HF toroid transformers can be downloaded from:

Programs. The following simple transformers using

toroid cores can be checked using these programs.

Simple Wire Wound HF Transformers For 50/75 Ohm Systems

The following diagrams and tables show some simple 1:1 and 4:1 baluns

for use between 1.8 and 30 MHz using twin transmission lines made from enamelled

copper wire (ecw). The baluns shown (except the current baluns) are voltage

(Ruthroff) baluns. The bifilar windings have been adjusted (spacing) to produce

transmission lines with Zo of 50 or 75 ohms as required for best matching.

These designs should be suitable for 100-200 Watt operation depending upon

operating mode.

Materials required:

- Ferrite Core: Select either rod or toroid core as detailed

below

- Core insulation: 1 layer of ptfe tape (plumbers thread

sealing tape); plumbing and hardware suppliers

- Wire: 1.0 or 1.25mm enamelled copper wire (ecw) as specified;

electronics shops

- Spacing material: Kinnears 540 TEX colourfil twine; product

code K 069048; newsagents, craft suppliers

Note: This spacing material is polypropylene; other

material is probably suitable, but ensure it will not absorb

moisture.

Winding Methods

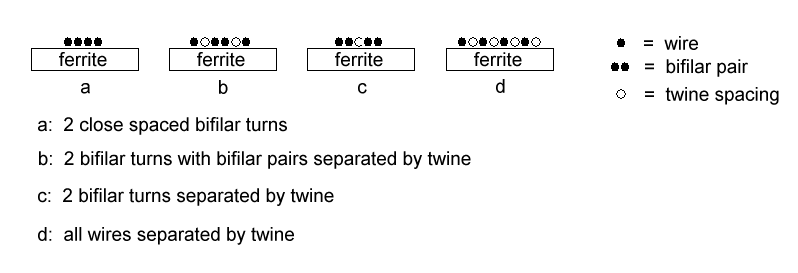

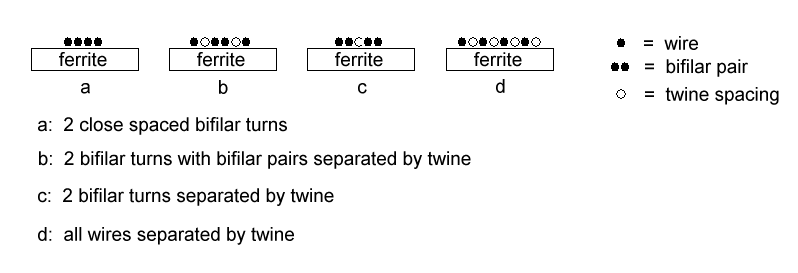

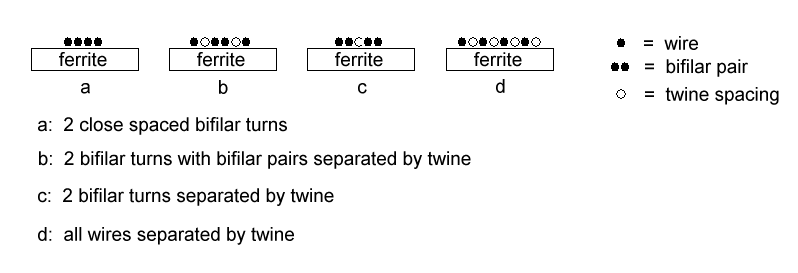

Examples of winding methods a, b, c, d on a rod.

Toroid core with 10 close spaced bifilar turns

1:1 Rod Balun

Ferrite Rod: R-61-037-300

Construction:

Start by winding a layer of ptfe tape on the rod

Cut two 750mm lengths of 1.25mm ecw for a bifilar winding.

Starting at the centre of the rod, close wind half the length of

the wires towards one end. Repeat for the other half. 15 bifilar

turns (2 wires) should now be centred on the rod, with sufficient

end lengths for terminations.

Cut the spacing twine into 750mm lengths and insert between the

wires as required by tightly pulling the cord between the turns.

This makes a secure finished winding. Start at the centre of the

winding and work towards each end.

For a 50 ohm balun put spacing twine between the bifilar turns

(winding method c).

For a 75 ohm balun put spacing twine between all wires (winding

method d).

Waterproof, terminate and house the finished balun as

required.

See test results for the rod

balun.

4:1 Rod Balun

Ferrite Rod: R-61-037-300

Use the same winding method and materials as in the rod balun

above.

Construction:

Cut two 750mm lengths of 1.0mm ecw for a bifilar winding.

Wind 15 bifilar turns centred and close spaced on the rod.

Wind spacing twine between all turns as described above (winding

method d).

See test results for this rod

balun.

1:1 Toroid Balun

Ferrite Toroid: FT-140-61.

Use the same winding method and materials as in the rod balun

above.

Construction:

Spread the 12 bifilar turns of 1.25mm ecw evenly around the core.

This leaves space between the 12 turns.

If the lowest operating frequency is 3.5MHz then 10 turns is

sufficient.

For a 50 ohm balun the bifilar pairs are close spaced (winding

method a).

For a 75 ohm balun put spacing twine between the bifilar

pair(winding method b).

See test results for these toroid

baluns.

4:1 Toroid Balun

Ferrite Toroid: FT-140-61.

Use the same winding method and materials as in the rod balun

above.

Construction:

Spread the 12 bifilar turns of 1.25mm ecw evenly around the core.

This leaves space between the 12 turns.

If the lowest operating frequency is 3.5MHz then 10 turns is

sufficient.

For the 50:200 ohm balun the bifilar pairs are close spaced

(winding method a).

For the 75:300 ohm balun put spacing twine between the bifilar

pair (winding method b).

See test results for these toroid

baluns.

06/12/10

homepage